Labeling management software to streamline packaging workflow

In this article, we’ll explore what labeling management software is, why it matters, and how it can transform your packaging workflows. Whether...

3 min read

Ekaterina Skalatskaia

:

May 1, 2025 10:30:00 AM

This article explores why global brands turn to labeling software for supply chain optimization. You’ll discover how centralized digital asset management, real-time proofing, and automated workflows eliminate errors, accelerate approvals, and improve compliance. We’ll break down the core benefits, share real-world success metrics, and guide you through the first steps to implement an enterprise labeling solution that keeps your products moving smoothly from factory floor to store shelves.

As global supply chains grow more complex—managing hundreds of products, dozens of markets, and strict regulatory requirements—manual labeling processes quickly become a bottleneck. Errors in artwork, mismatches in translations, or delays in approval can cost thousands in rework, fines, and missed launch windows. That’s why leading enterprises are investing in purpose-built labeling software: to streamline operations, mitigate risk, and deliver products faster and more reliably.

In this article, we’ll explore six ways Cway’s enterprise labeling software empowers global brands to optimize supply-chain workflows, share a real-world success story, and outline five simple steps to get started.

Smarter Artwork Approvals Start Here

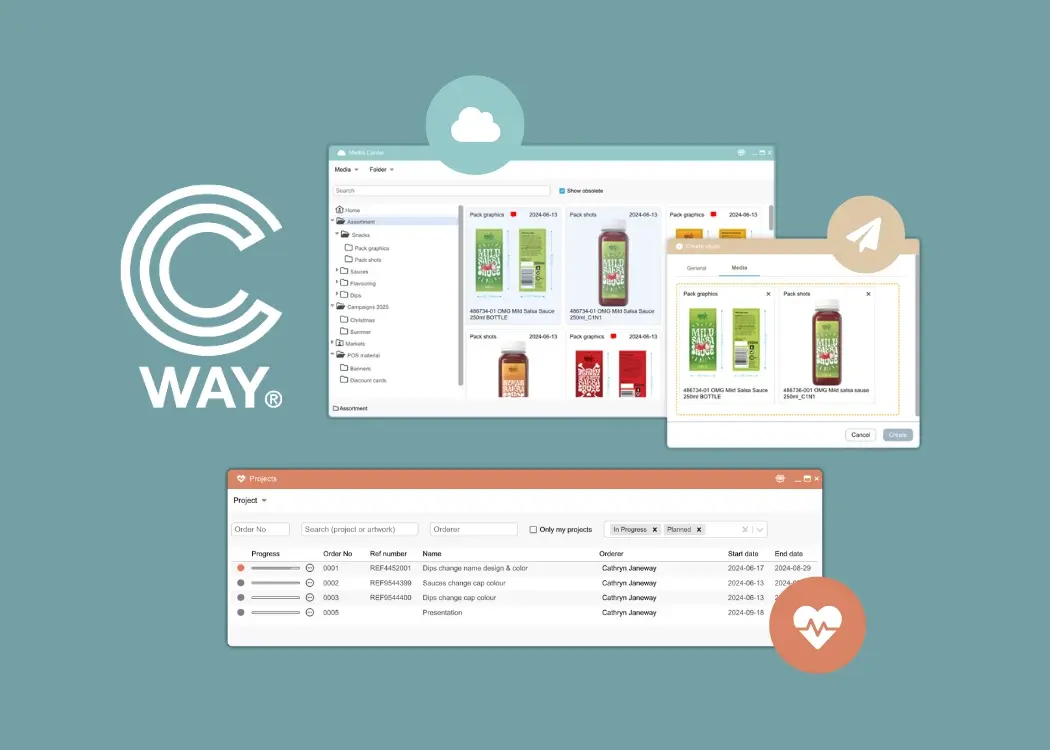

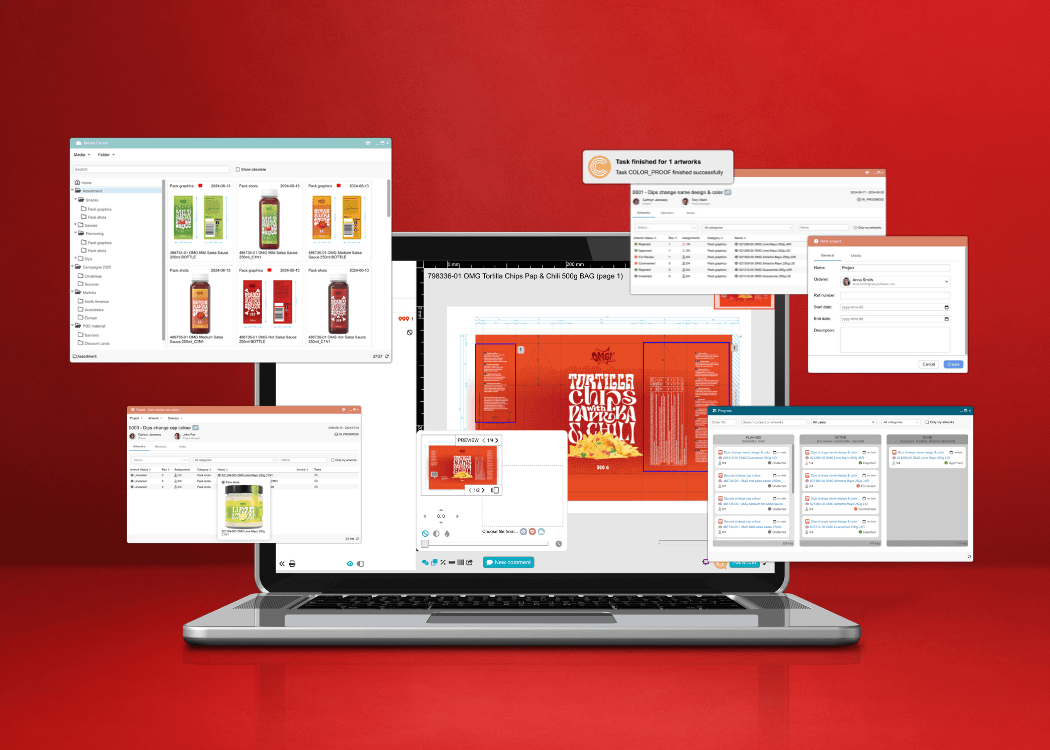

Discover Cway® – your all-in-one design and content approval platform.

Millions of SKUs, dozens of markets. Each country has unique languages, regulations, and artwork requirements.

Fragmented tools & silos. Design teams use one system, regulatory teams another, and logistics yet another—making traceability a nightmare.

High stakes for errors. A single labeling mistake can trigger recalls, regulatory fines, or hold shipments at customs.

Time-to-market pressure. In fast-moving consumer goods and pharma, speed is a competitive advantage.

Enterprise labeling software tackles these challenges head-on by centralizing assets, standardizing workflows, and giving every stakeholder real-time visibility into the process.

Store all packaging assets—artwork files, approved templates, regulatory text—in one secure repository. Version control ensures everyone uses the latest files, and role-based permissions keep sensitive content protected.

“Cway’s DAM saved us endless back-and-forth emails. We now find any label variation in seconds and know it’s been approved.”

—Sofia Wallsten, Product Manager, Fria Bröd

Automatically merge product data (ingredients, nutritional info, barcodes) into approved templates. When formulas or regulations change, labels update system-wide—no manual edits needed.

Built-in PDF proofing with redline annotations and live comments means design, legal, and marketing teams collaborate seamlessly. Automated notifications keep approvals on track; no more chasing signatures.

Cway connects bi-directionally with ERP, PLM, and WMS platforms. Data flows automatically between systems, eliminating double-entry errors and ensuring that packaging specs always match production orders.

Every action—who changed what, when, and why—is logged. Granular audit reports help you demonstrate regulatory compliance for FDA, EU FCM, or any global standard, reducing risk in audits and inspections.

Dashboards surface bottlenecks (e.g., slow approvals, high revision rates) and key metrics (average time-to-approve, error frequency). Use these insights to refine processes, train teams, and measure ROI.

When Fria Bröd decided to launch a gluten-free line across Scandinavia, their traditional labeling process couldn’t keep up. Translating nutritional tables into five languages, maintaining brand consistency, and securing regulatory sign-off in three countries took weeks—and errors slipped through.

By switching to Cway’s enterprise labeling software, Fria Bröd:

Reduced label approval time by 60%

Cut artwork revisions by 75%

Achieved 100% on-time launches in all markets

Deep dive: Fria Bröd packaging-approval case study

Define Your Asset Structure

Map out how you organize templates, regional variants, and language files. Cway’s onboarding team will help you translate that into your DAM taxonomy.

Integrate Core Systems

Connect your ERP or PLM so that product master data and compliance info flow into Cway automatically.

Configure Workflows & Permissions

Set up approval chains—marketing → legal → regulatory—and assign roles so each stakeholder sees only the tasks relevant to them.

Migrate & Validate Assets

Import your existing artwork and templates. Our audit tools flag missing fonts, low-res images, or compliance gaps before they become problems.

Train & Launch

Run interactive workshops for designers, brand managers, and operations. Then go live—your global labeling process will be faster, error-free, and fully auditable from Day 1.

Minimal. Cway® offers prebuilt connectors for most major ERPs and a REST API for custom integrations. Our team collaborates closely with your IT group.

We use end-to-end encryption, SOC 2–compliant infrastructure, and granular access controls. You retain ownership of all assets at all times.

Absolutely. You can configure templates and build approval chains that match your organizational roles—so marketing, legal, and QA each see only the steps they need.

In this article, we’ll explore what labeling management software is, why it matters, and how it can transform your packaging workflows. Whether...

In the world of fast product turnarounds and evolving compliance standards, managing packaging artwork isn’t just about graphic design—it’s about...

Streamline design approvals, enhance feedback loops, and get to market faster with Cway®—your all-in-one platform for artwork approval process.