Side-by-side packaging artwork comparison—simplified with Cway®

Ever tried approving packaging artwork by email? It's a game of "Which version are we on again?" followed by "Oops, that wasn’t the final one"—and...

4 min read

Ekaterina Skalatskaia

:

May 30, 2025 7:15:00 AM

You’ve probably been there: 10 rounds of artwork edits, 4 people CC’d on a PDF, and a folder full of files named Final_v3_THIS_ONE_USE.pdf. Meanwhile, the printer is asking for confirmation, your marketing manager wants to “just tweak one more thing,” and no one can say for sure which file is actually approved.

Welcome to the everyday struggle of packaging artwork version control gone wrong—where even small missteps can lead to expensive errors, product delays, or full reprints.

If your packaging workflow still relies on email threads, cloud folders, and guesswork, it’s time to rethink how you manage your files—and your sanity.

Version control is the process of tracking, managing, and documenting changes to your packaging design files throughout the artwork lifecycle.

It ensures that:

Everyone is working on the latest version

Previous versions are saved, accessible, and clearly documented

Changes are reviewed and approved before moving forward

No one accidentally sends the wrong file to print or market

Think of it as Google Docs for packaging artwork—but with more structure, visibility, and traceability.

Discover best practices for artwork reviews, feedback, and version control—without the chaos.

Let’s take a closer look at the risks that companies face when version control is missing or poorly managed:

Files named “FINAL_v5” and “FINAL_THIS_ONE.pdf” don’t help anyone. When files are scattered across email threads, desktops, or random cloud folders, it becomes impossible to know which is correct.

Example: A cosmetics brand once shipped 50,000 boxes with outdated sustainability claims due to uploading an older PDF to their printer’s FTP. The updated eco-certification version never made it into production.

With no visibility into who changed what or when, errors slip in. And in regulated industries like food or pharma, compliance missteps can lead to serious consequences.

Example: In 2021, a Canadian snack brand had to recall an entire batch due to omitted allergen labeling—they had mistakenly approved a file meant for a different region.

When version control isn’t enforced across product lines, teams may accidentally use a design template from another size, market, or even product.

Example: A beverage company accidentally printed English-only packaging for a bilingual market in Quebec, violating legal packaging laws and causing a retail pullback.

Explore our powerful packaging workflow tools—no strings attached. Start optimizing your artwork process today.

If you’re not using a dedicated artwork version control tool, chances are you’re relying on some of these workarounds:

Email Threads

Versions float around in attachments. Chaos ensues. No central history, no reliable approval record.

Shared Drives (Dropbox, Google Drive)

They offer basic file access, but not structured workflows. Users can easily overwrite files, miss updates, or comment out of context.

Designers can version manually—but these tools weren’t built for project-wide collaboration across marketing, compliance, and supply chain teams.

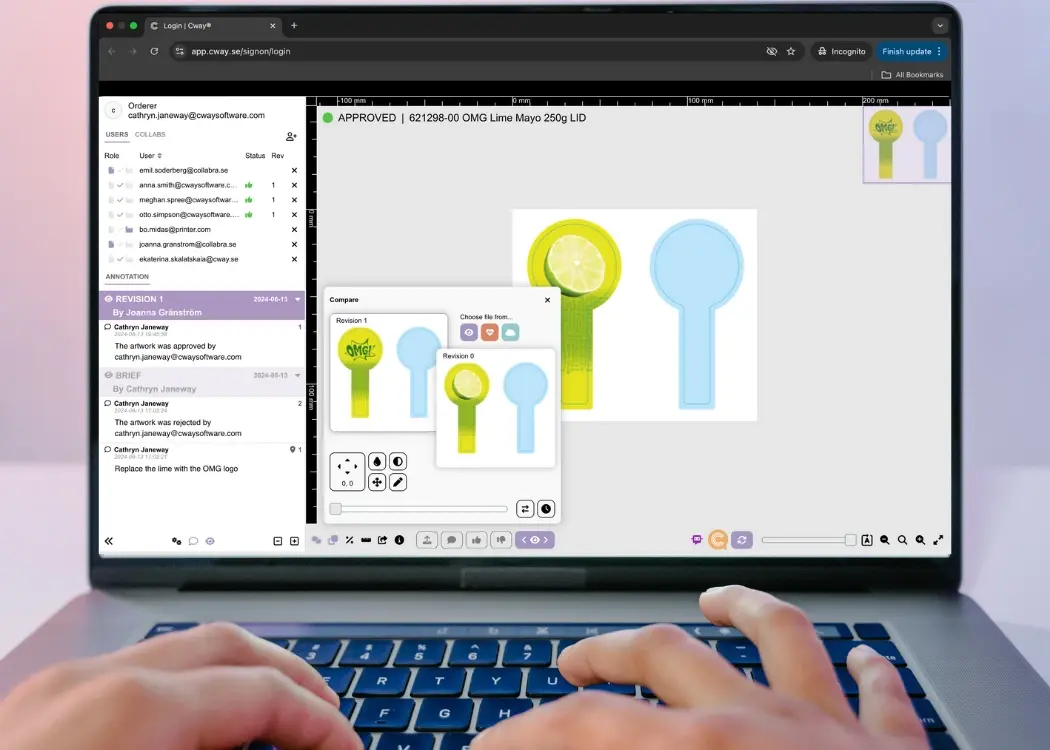

Cway® brings real version control into your packaging process with two key tools: Compare Tool and Version Timeline, both built into the Cway Viewer.

You can compare any two files—whether they’re versions within a project or assets across your organization.

Blink mode: Alternates files so you can spot even the smallest visual difference

Transparency & contrast controls: Overlay files to highlight subtle changes

Align & shift tools: Perfectly match layouts that moved slightly

Cross-project comparison: No need to switch tabs or open external software

✅ No more flipping between PDFs

✅ No Illustrator licenses required

✅ Everyone sees the same thing

Every artwork file in Cway® comes with a clear, navigable timeline that shows:

Who made each revision

What comments were added

Which versions were approved (and by whom)

Complete artwork lifecycle history

This gives your team confidence, accountability, and an audit trail you can actually use.

Book a free consultation with our experts. We’ll audit your current artwork process and help you identify bottlenecks, delays, or version risks—no strings attached.

Faster approvals: Reduce back-and-forth with one centralized visual review space

Fewer errors: Catch problems before they go to print

Full transparency: Everyone sees the same version, history, and decisions

Better compliance: Keep records for legal, regulatory, and QA audits

Version control isn’t just about file names—it’s about protecting your brand, avoiding expensive errors, and empowering your team to work with confidence.

Cway® helps you:

Compare designs with clarity

Track every revision

Maintain a single source of truth

Approve faster, and smarter

Version control refers to the process of managing and tracking all changes made to packaging design files over time. It ensures that teams are always working from the correct version, and that every edit, comment, and approval is documented throughout the artwork lifecycle.

Without proper version control, packaging teams risk using outdated files, introducing errors into the design, or even sending the wrong artwork to print. This can result in product recalls, compliance issues, and expensive reprints—especially in highly regulated industries.

Yes. Cway® allows you to compare files across projects and even from your asset library. This is especially useful for brands managing multiple SKUs, regions, or product lines with shared design elements.

No. Version control is critical for everyone involved in packaging—including marketing, compliance, regulatory, legal, operations, and suppliers. It ensures that each stakeholder is reviewing the correct version of the artwork and that approvals are based on accurate files.

Teams without version control often face:

Confusion over file status

Delays in approvals and time-to-market

Errors caused by outdated artwork

Lack of accountability in the review process

Costly mistakes and potential compliance issues

Ever tried approving packaging artwork by email? It's a game of "Which version are we on again?" followed by "Oops, that wasn’t the final one"—and...

Creating packaging isn’t just about great design—it’s about building an approval workflow that ensures every step, from concept to shelf, is aligned,...

Up to 70% of packaging delays are caused by artwork-related issues.When file versions get mixed up or approvals go off-track, launches stall and...